APG's New and Refurbished Parts: Enhancing Your Industrial Gas Turbine Performance

We at Allied Power Group (APG) are proud to be the top supplier of industrial gas turbine maintenance, repair, and field services. With a focus on maximizing the availability, reliability, and efficiency of our customers' power-generating assets, we offer the highest level of technical expertise to meet the mission-critical demands of the power industry.

Comprehensive Inventory of Combustion Parts

APG's Combustion Parts stand out among our diverse selection as evidence of our dedication to quality and accuracy. Our cutting-edge Farrell Road plant in Houston, Texas, painstakingly crafts these combustion liners, caps, and transition components. We make sure that every component is expertly made, enabling easy integration and top performance in your gas turbine.

Superior Shrouds for Enhanced Performance

APG's 7EA Shrouds are designed with superior materials compared to the OEM's current selections, enabling multiple repairs beyond what the OEM offers. Our shrouds are designed for increased longevity and efficiency, adding to the overall dependability of your gas turbine. Options include:

STAGE 1 SHROUD

HR 120 or SS310

TBC or Metallic Coated

STAGE 2 SHROUD

SS310

Honeycomb

STAGE 3 SHROUD

SS410

Honeycomb

Refurbished Industrial Gas Turbine Parts and Components

As a trusted name in the industry, APG specializes in providing top-quality refurbished industrial gas turbine parts and components. All of our components are rigorously examined, reconditioned, and held to the highest standards as part of our dedication to excellence before they are made available for use in your gas turbine. We strive to serve a variety of gas turbine models, such as GE Frame 3, GE 6FA, GE Frame 5, GE 7/9E, GE Frame 6B, GE 7F/FA, W501D5/5A, and W501F, by providing a wide range of reconditioned components.

| GE Frame 3 | GE 6FA |

| GE Frame 5 | GE 7/9E |

| GE Frame 6B | GE 7F/FA |

| W501D5/5A | W501F |

Advantages of Choosing Refurbished Parts

There are several advantages to using refurbished industrial gas turbine components. In addition to providing considerable cost savings over buying brand-new components, they also assist in minimizing downtime so that your gas turbine can rapidly resume operating at its best. Thanks to our meticulous refurbishing procedure, you can be sure that these components will satisfy OEM requirements and add to the durability and effectiveness of your gas turbine.

Refurbished Capital Components for Optimal Reliability

We are aware of how crucial capital components are to the functionality of your industrial gas turbine. Because of this, we provide capital components for industrial gas turbines that have been reconditioned and uphold the highest standards of quality and dependability. These parts go through a thorough refurbishing procedure to ensure they are ready to operate in your gas turbine at their peak efficiency.

Responsive Generator Repair Services

APG offers prompt generator repair services to take care of any problems with your power producing assets in addition to high-quality parts. Our team of professionals is prepared to handle generator repair close to you to ensure that your equipment runs effectively and dependably. Our generator repair service is specialized to match your needs, whether you need routine maintenance or assistance with a particular issue.

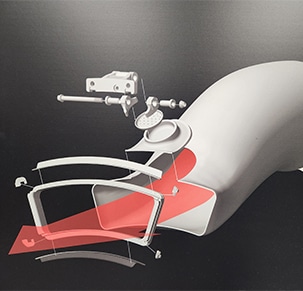

Unmatched Turbine Components Manufacturing

We are committed to developing turbine components that go above and beyond industry requirements as a renowned manufacturer of turbine parts. Our cutting-edge manufacturing techniques are closely scrutinized to assure accuracy and quality in every item we make. You have access to a large selection of high-quality turbine spares when you pick APG as your supplier of turbine components, assuring the smooth running of your gas turbine.

Expert Compressor Repair Services

Your gas turbine will run at its best when the compressor is in good working order. The purpose of APG's compressor repair services is to increase the efficiency and dependability of your compressor. Utilizing the most up-to-date equipment and methodology, our team of knowledgeable specialists will repair your compressor utilizing proven ways.

Maximize Efficiency with APG's Gas Turbine Services :

Comprehensive Solutions for Gas Turbines

APG offers gas turbine services to improve the effectiveness and performance of your power production assets. Our skilled staff carefully examines and evaluates the parts of your gas turbine, locating any that need repair or replacement. We make sure that your gas turbine runs properly and satisfies your need for power production through our extensive overhaul procedure.

Advanced Rotor Refurbishment for Extended Lifespan

Advanced rotor refurbishing is a specialty of APG's gas turbine repair services. Our qualified engineers and technicians use modern processes to repair and restore rotor components, prolonging their lifespan and performance. You may greatly decrease the need for pricey replacements and increase your gas turbine investment return by selecting APG's rotor refurbishing options.

To satisfy your industrial gas turbine demands, we at Allied Power Group are committed to providing the finest quality service and knowledge. Our goal is to maximize the effectiveness and dependability of your power generating assets by using high-quality reconditioned components and quick generator repair services. You can depend on APG to be your partner in guaranteeing the efficient operation of your gas turbine and that you can confidently fulfill the needs of electrical power consumption.